"...the accumulated past is lift's best resource for innovation ...reinventing beats inventing nearly every time." Stewart Brand

Examples:

- Shape-memory polymers to mimic natural movement

- 'Lotus effect' nano-coatings

- Velcro

- Austerity repair

- Make-do-and-mend

- D.I.Y/punk customization

- Modern nomads

- Historic dying/ printing techniques

Mortortex

Morphotex butterfly which used the scales on their wings to reflect the light in different ways in order to maintain a vivid, bright blue with shimmer in their wings.

"Teijin Fibers Ltd. started the commercial production of Morphotex, which is an unstained, structurally colored fibre. This technology is based on the biomimetic conception for the microscopic structure of Morpho butterfly's wing, Thin films of 70 nm thickness consisting either of polyester or nylon are laminated in 61 layers alternatively, and four types of basic colors such as red, green, blur and violet are allowed to be developed by precisely controlling the layer thickness according to visible wavelength. Morphotex has wide applications, e.g. filament, short-cut fiber and powdery materials." kenkichi (2005)

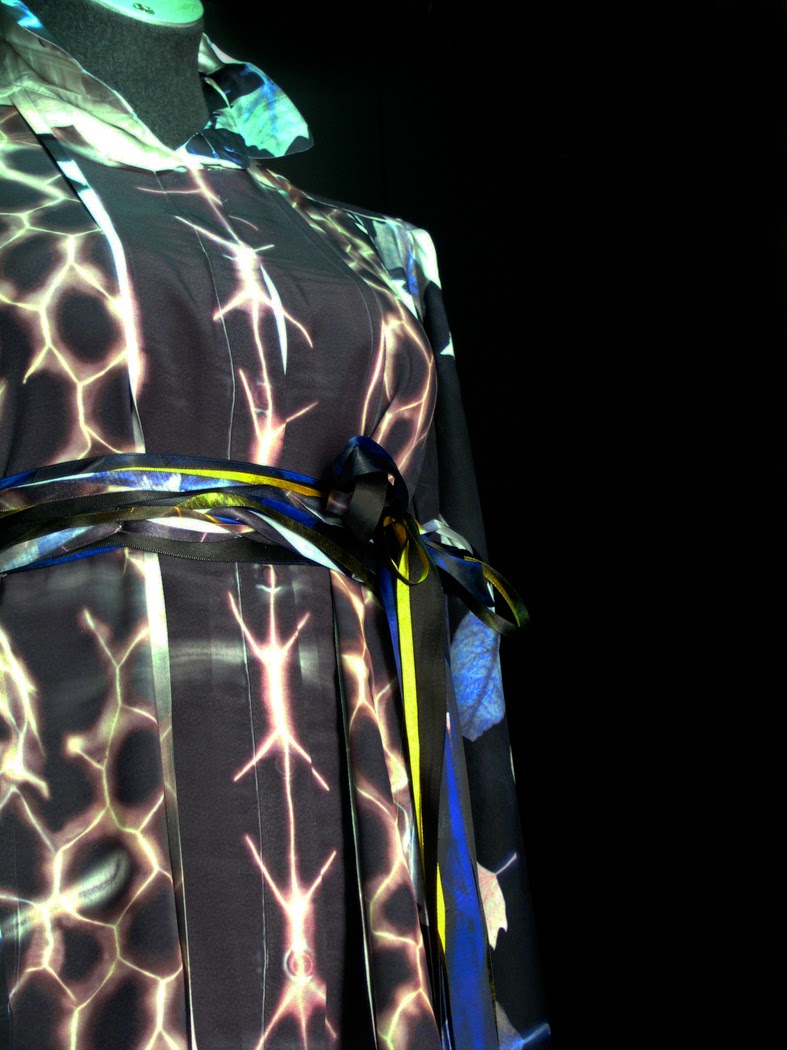

This dress is purely a trick of the light, Sydney designer Donna Sgro used Morphotex a technology-based, structurally colored fibre that mimics the microscopic structure of the Morpho butterfly's wings. Manufactured in Teijin, Japan, morphotex requires no inks, dyes or pigments, nor excessive water consumption or industrial waste as no energy is being used.

This project is really inspired me, because basically I'm interesting in textile technology. I knew an traditional dye technique is still useful for now. Moreover in Thailand Thai Silk is very poplar product in Thailand and very famous in the world. Thai Silk has unique quality and shine, they have reflect with the light. For this project, I realize that we can use new technology create a new fibre for same quality as made from nature material with out any dyes.

Reference

Chua, J Malik. (2010) "Morphotex" Dress Mimics Butterfly Wing Shimmer--Without Any dyes. [Online] Available from: <http://www.ecouterre.com/morphotex-dress-mimics-butterfly-wing-shimmer-without-any-dyes/> [Accessed 4 January 2015]